UNDERFILL MATERIALS

Underfill Materials

Description

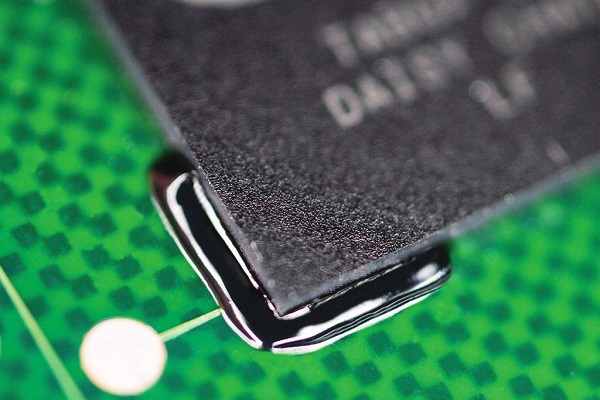

Underfill materials are specialized adhesives used in the semiconductor industry to improve the reliability of flip chip packages, which are commonly used in microprocessors, memory devices, and other electronic components.

Flip chip packages consist of an integrated circuit chip that is mounted upside down and bonded directly to a substrate or printed circuit board using solder bumps or balls. Underfill materials are used to fill the gap between the chip and the substrate, providing additional mechanical support and reducing stress on the solder joints during thermal cycling.

Underfill materials are typically two-part epoxy adhesives that are applied to the chip-substrate interface using a dispensing system. The adhesive is then cured or hardened using heat or ultraviolet light, forming a strong and durable bond between the chip and substrate.

Underfill materials offer several benefits in the semiconductor industry, including improved reliability, increased thermal and mechanical stability, and enhanced resistance to vibration and shock. They also help to reduce the risk of failure due to factors such as moisture, temperature cycling, and mechanical stress.

There are various types of underfill materials available in the market, including capillary flow and no-flow underfills, and different formulations are designed to meet specific performance requirements. Capillary flow underfills are designed to flow into the gap between the chip and substrate using capillary action, while no-flow underfills are formulated to stay in place without flowing.

The selection of the appropriate underfill material is dependent on various factors such as the specific flip chip design, substrate material, and manufacturing process. Manufacturers offer a wide range of underfill materials with different viscosities, curing times, and other properties to suit different applications.

Overall, underfill materials play a critical role in improving the reliability and performance of flip chip packages, ensuring that electronic components are able to function effectively and efficiently over their lifetime.

| Description | Capillary-Flow, Curing, Process Conditions | Modulus (GPa) | CTE (ppm/°C) | Tg (°C) | Dielectric Constant/Loss (1MHz) | Ionic Impurities (Na+, K+, Cl-, etc.) |

|---|---|---|---|---|---|---|

| Quartz filled Liquidous mixture Ultra low CTE | Capillary flow @40-80°C Curing @ 150°C/90 sec | 7.5 | 19 | 236 | 3.8/0.01 | < 10 ppm |

| Alumina filled Liquidous mixture Thermally conductive | Capillary flow @40-80°C Curing @ 150°C/90 sec | 7.5 | 20 | 236 | 4.2/0.01 | < 10 ppm |

Order Form

About Semiconductor Electronics

SEMI EL project is a global supplier of materials, equipment, spare parts and supplies for the semiconductor industry.

Get In Touch

Email: info@semi-el.com